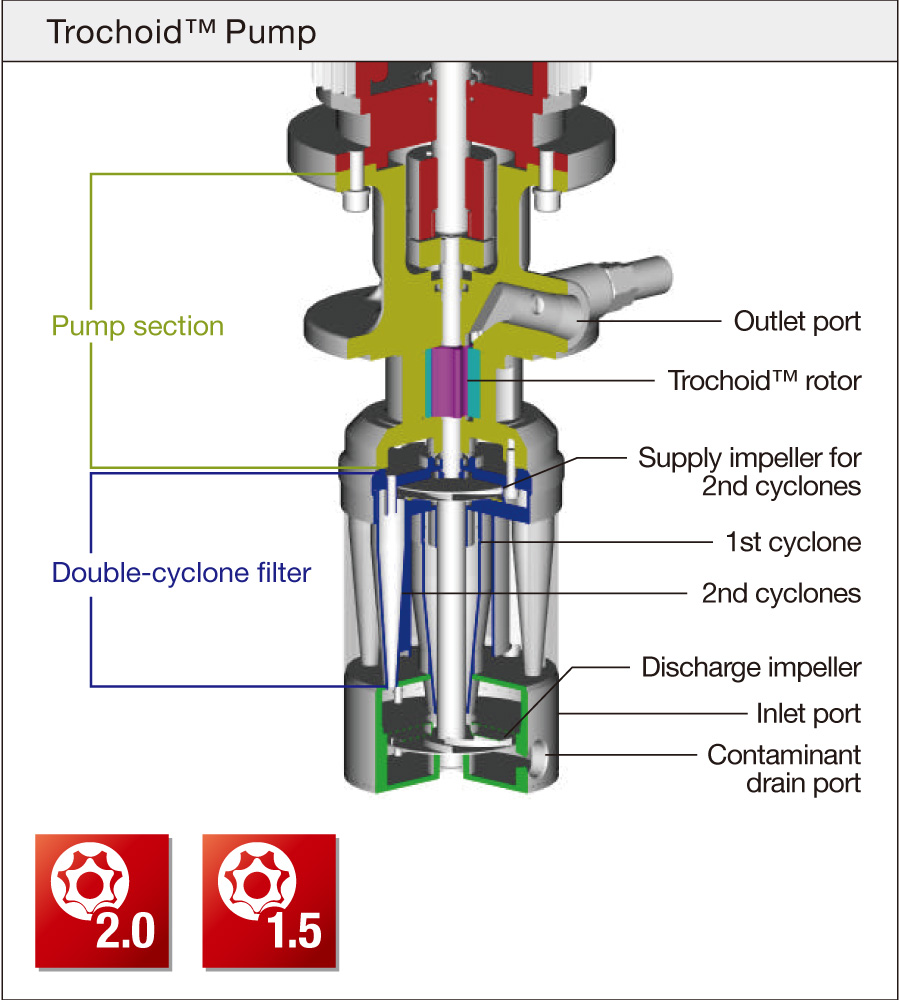

Trochoid™ Type

Medium Pressure Unit

- Double-cyclone filter

-

Two layers of double cyclones (one large cyclone and six small cyclones) remove sludge from the coolant fluid.

- Trochoid™ pump/2.0 MPa, 1.5 MPa

-

A rotor turning in a trochoidal curve generates pressure to suck and discharge fluid. This is an extremely efficient self-priming pump.

FEATURES

YTH-CT/CS

All-in-one Medium-pressure

Coolant Pump

All components of a coolant system are consolidated into a single pump. The saved space expands the available plant space, resulting in a higher production efficiency.

- Maximum operating pressure: 2.0 MPa.

- Maximum flow rate: 28.8 liters/min.

- No suction filter is required.

- No plumbing is required to interconnect various components.

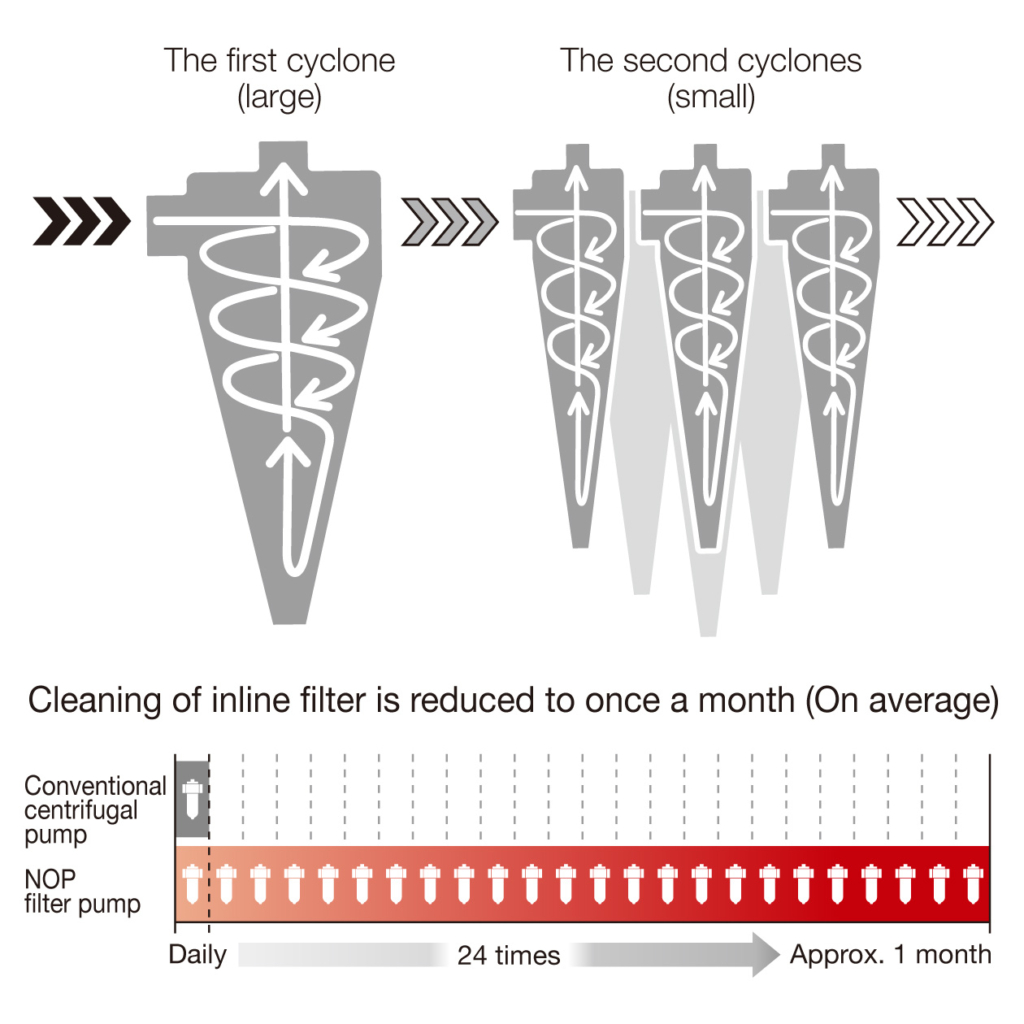

Double-cyclone Filter

A proprietary double-cyclone system removes sludge.The first cyclone removes larger debris, while the second cyclones remove smaller particles. The inline filter cleaning cycle is extended by 24 times.*Sludge larger than 20 μm can be removed. (When using water-soluble coolant fluid.)

High Efficiency Trochoid™ Pump

CT employs a Trochoid™ pump which excels in fluid control efficiency. The double-cyclone system sorts out sludge and enables direct connection to the coolant tank.

- Compatible fluid type

- Water soluble coolant.

- Incompatible with non-water soluble coolant, lubricant oils, fuel oils.

- Incompatible with clear water, demineralized water, aqueous solutions and viscous fluids without rust-preventive property, corrosive fluids, solvents, oil-based materials.

- Relief valve is built into the pump.

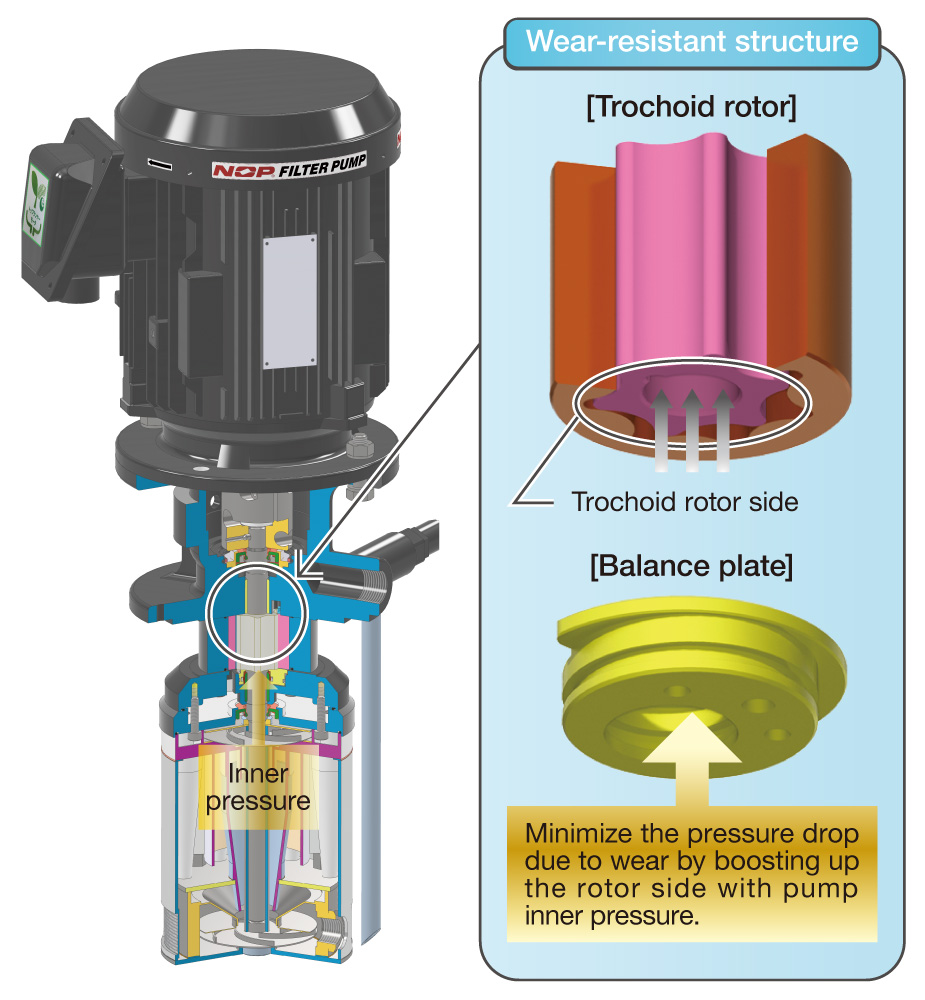

YTH-CS Type (Wear-resistant Model)

For its special wear resistant structure, YTH-CS can be installed on coolant tanks of machines that generate hard and abrasive swarf that YTH-CT cannot handle.

- Balance Plate

- Pump generates inner pressure to press the balance plate toward the Trochoid rotor side, which helps in reducing the clearance created by wear on rotor side and thereby minimize the pressure drop, ensuring desired performance for a longer time.

- Shaft and Bearing Reinforcement

- Improved wear resistance by employing sprayed ceramic on shaft bearing area and use of ceramic bearing.

- Double Seal & Cartridge System

- Seal area is reinforced to prevent leakage and cartridge system ensures ease of replacement.

Filter Rating (Nominal value)

| Suction strainer | 3 mm (Solids larger than this must be removed from the tank.) |

| Filter | Water-soluble coolant fluid 50 μm: 95% (Specific weight 2.7) 100 μm: 99.9% (Specific weight 2.7) |

Corresponding Chip Type

MODEL NUMBERING SYSTEM

YTH-CT/CS

MODEL NUMBERING SYSTEM

TOP-YTH ① ② – ③ C VD ④

| ①Motor Capacity | 750: 0.75 kW 1500: 1.5 kW |

| ②Motor Type*1 | [Standard Motor] A3: AC 200/200/220/230 V 50/60/60/60 Hz 3 phase electric induction motor (IE3) with CE marking [Local Motor] AE: supplied by NOP Germany AF: supplied by NOP Taiwan AJ: supplied by NOP Asia (China) AK: supplied by NOP India AU/AV: supplied by NOP North America (USA) |

| ③Pump Capacity (Trochoid™ pump) | T208: 8 cc/rev T216: 16 cc/rev S216: 16 cc/rev |

| C: Filtering Method | Double cyclone |

| VD: Relief Valve | External return type |

| ④Relief Pressure Setting*2 | 20: 2.0 MPa 15: 1.5 MPa |

*2 The valve set pressure for model S216 is fixed at 2.0 MPa. 1.5 MPa is unavailable.

SPECIFICATIONS

| 形 式 | Motor Capacity (kW) | Flow Rate (L/min) 50 Hz/60 Hz | Maximum Pressure (MPa) 50 Hz/60 Hz | Approximate Weight (kg) |

| YTH750A3-T208CVD* | 0.75 | 12.0/14.4 | 2.0/2.0 | 34 |

| YTH1500A3-T216CVD* | 1.5 | 24.0/28.8 | 2.0/2.0 | 39 |

| YTH1500A3-S216CVD20 | 1.5 | 24.0/28.8 | 2.0/2.0 | 39 |

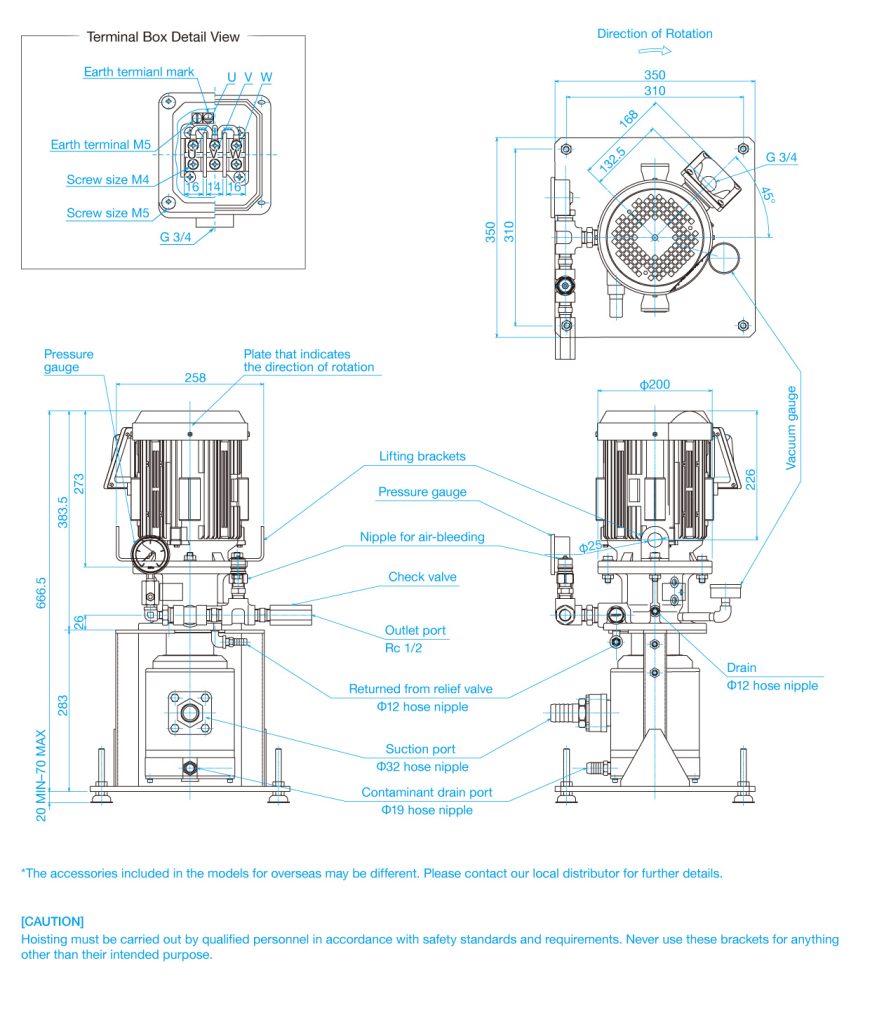

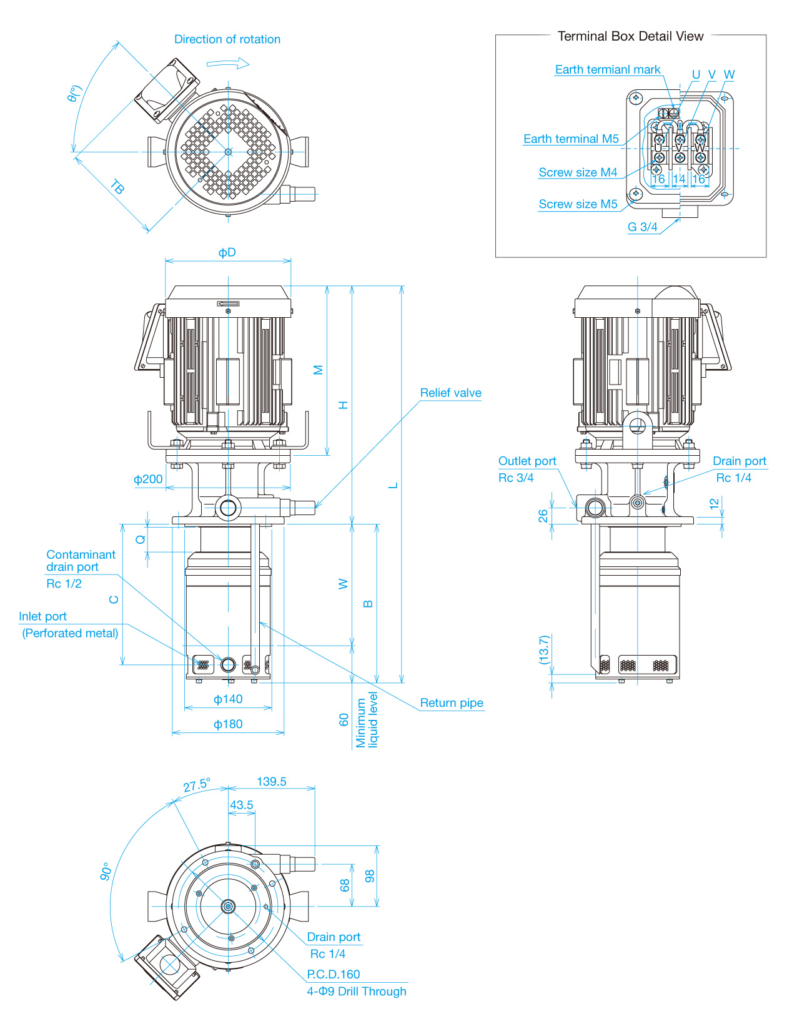

DIMENSIONS

YTH-CT/CS

Typical/Motor Type: A3

| 形式 | L | B | C | W | Q | H | M | φD | θ(°) | TB |

| YTH750A3-T208CVD* | 599.7 | 235.7 | 206.7 | 175.7 | 20 | 364 | 253.5 | 170 | 30 | 151 |

| YTH1500A3-T216CVD* | 639.2 | 255.7 | 226.7 | 195.7 | 40 | 383.5 | 273 | 202 | 45 | 168 |

| YTH1500A3-S216CVD20 | 643.7 | 260.2 | 231.2 | 200.2 | 40 | 383.5 | 273 | 202 | 45 | 168 |

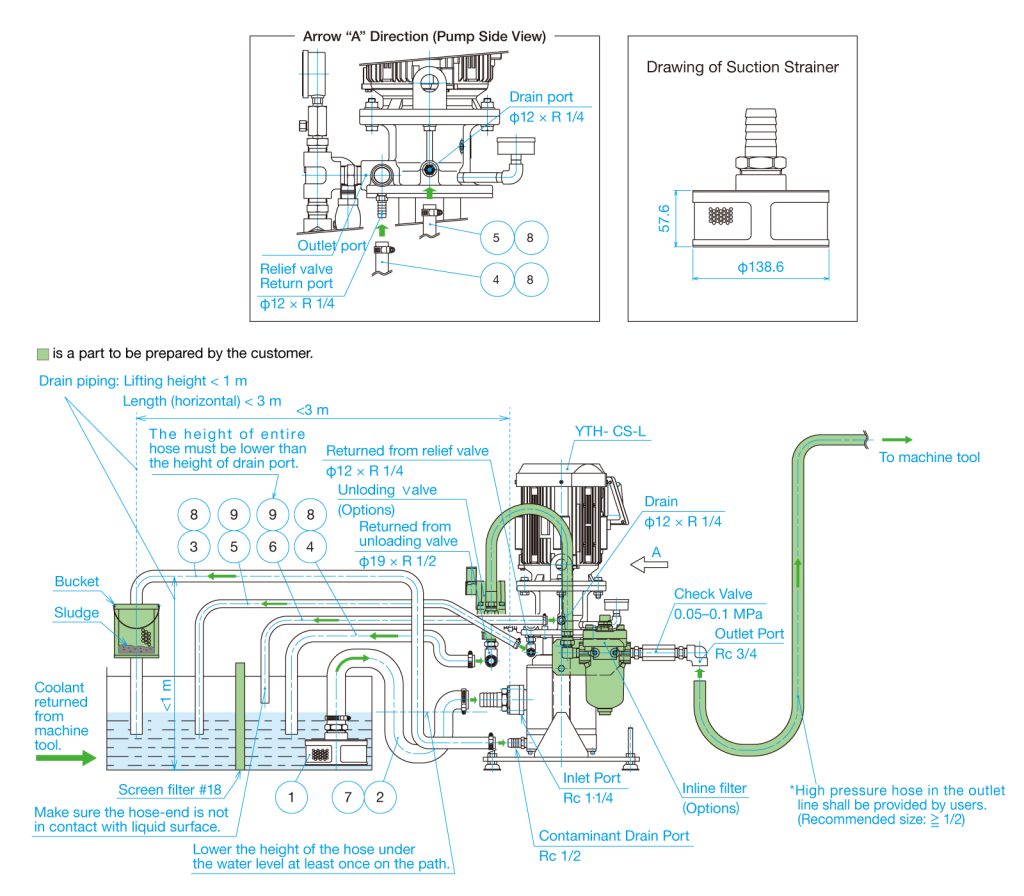

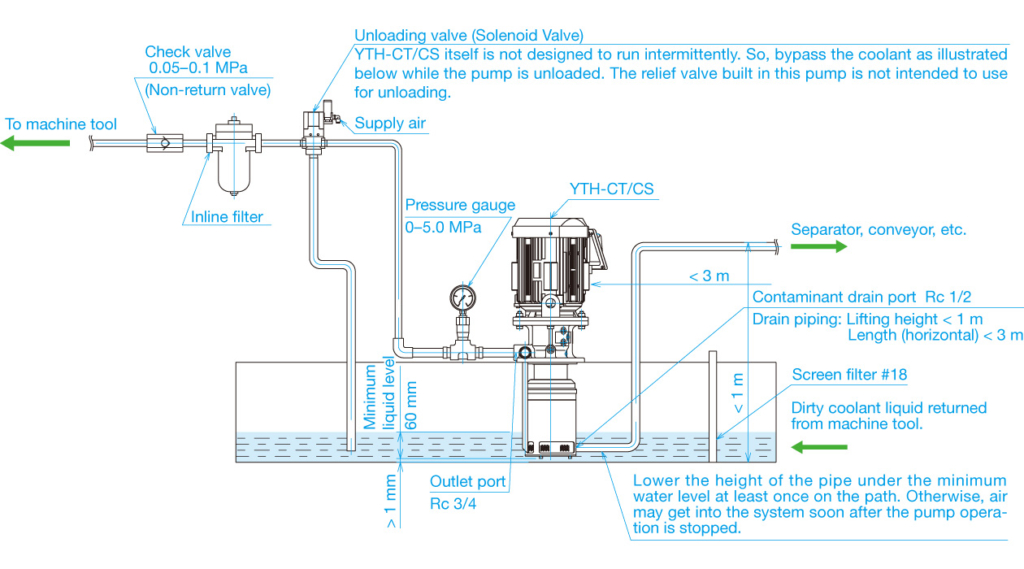

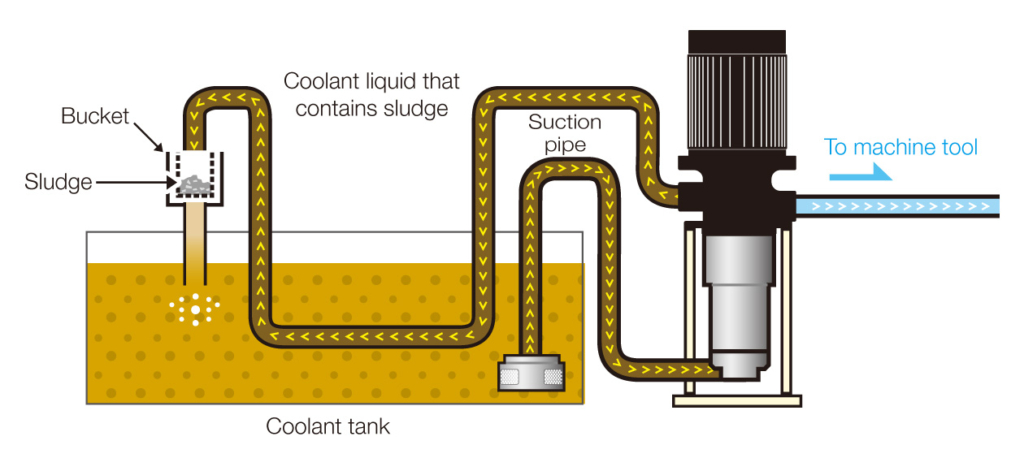

SAMPLE SYSTEM LAYOUT

YTH-CT/CS

Please be sure to read the instruction manual before use.

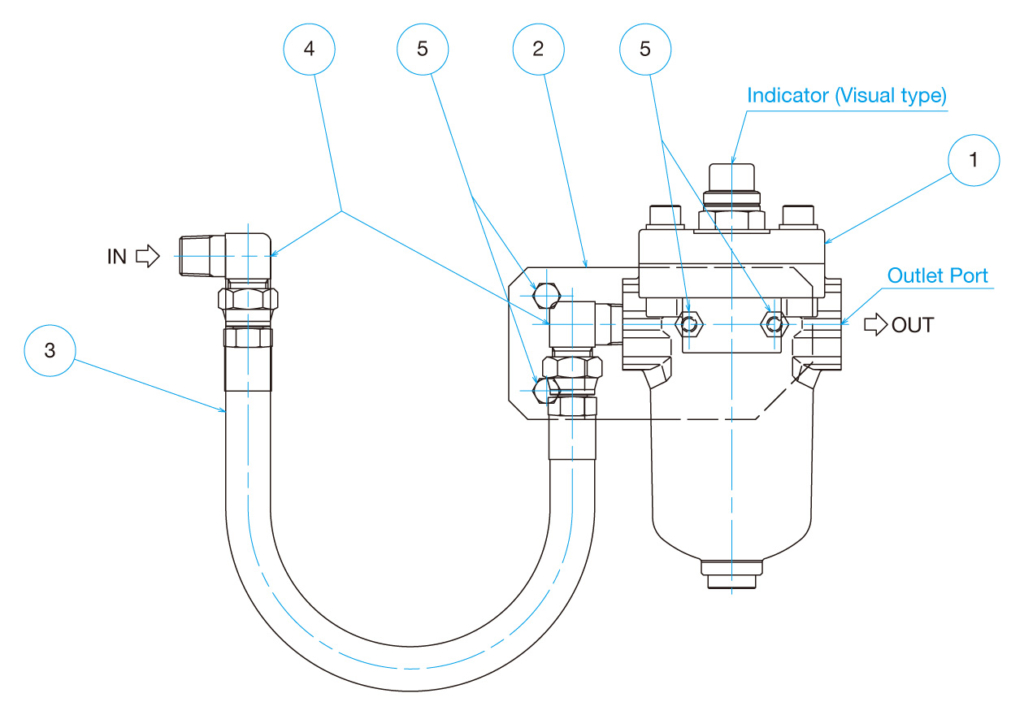

Peripheral Options

INLINE FILTER

■Accessories

| No. | Part Name | Qty. |

|---|---|---|

| 1 | Inline filter Drawing No./Model No.: M-KL-04-20UW-EK Taisei Kogyo Co.,Ltd. | 1 |

| 2 | Filter bracket for CS-L | 1 |

| 3 | Pressure rubber hose 1/2 × 500 mm with metal fitting on both sides | 1 |

| 4 | Hose adapter 15 A × G15 Elbow | 2 |

| 5 | Hexagonal bolt M8 × 16 SCM trivalent chromate | 4 |

■Filter Specification

| Compatible Liquid | Water-glycol fluid, etc. |

| Connection Port | Rc 1/2 |

| Nominal Filtration Rating | 20 μm |

| Indicator | Electric contact type (Working pressure: 0.3 MPa) |

| Relief Valve | Non |

| Surge Suppressor | Installed |

| Mating Flange | Non |

| Magnet | Non |

| Maximum Operating Pressure | 3.5 MPa |

| Element Differential Pressure Resistance | 0.7 MPa |

| Standard Flow Rate | 50 L/min |

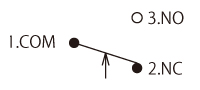

■Microswitch contact capacity

| Resistive load | 3A、250VAC 3A、30VAC |

| Inductive load | 2A、250VAC 2A、30VAC |

| Minimum load | 160mA、5VAC 100mA、100VAC |

| Contact |  |

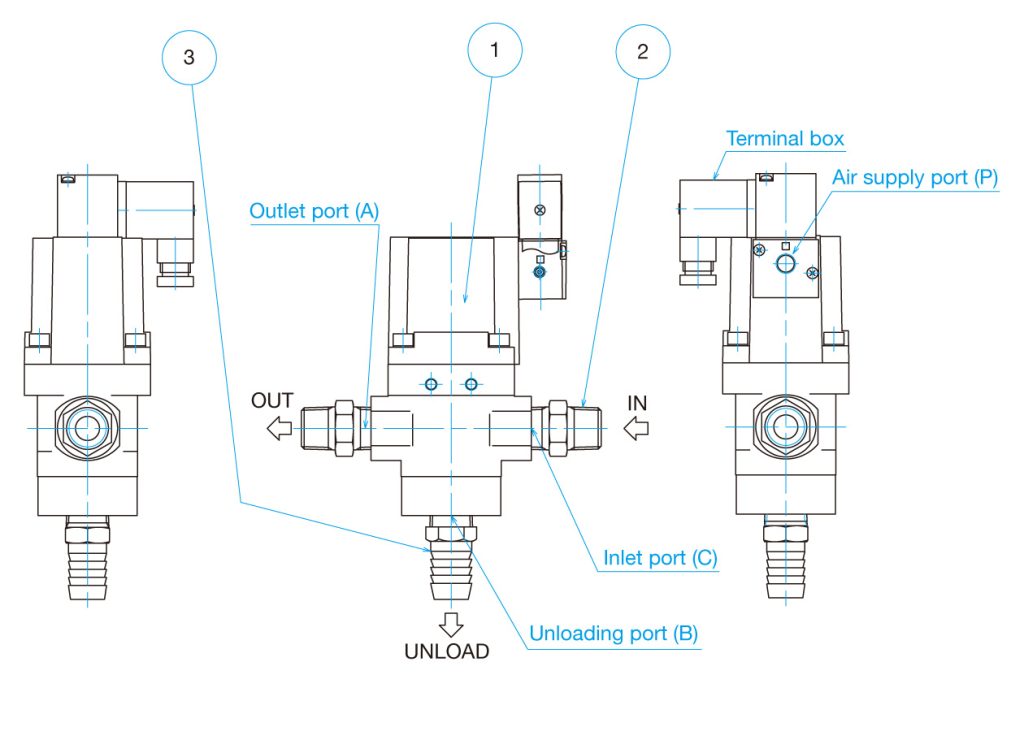

UNLOADING VALVE

■Accessories

| No. | Part Name | Qty. |

|---|---|---|

| 1 | Unloading valve Drawing No./Model No.: CVSE3-15A-35-B2GS-3 CKD | 1 |

| 2 | High pressure nipple 15 A | 2 |

| 3 | Hose nipple Φ19 × 15 A | 1 |

■Electrical Specifications

| Required Power | 2.0 W |

| Heat Resistance Class | 130 (B) |

| Protection Level | IPX5 (IEC 529) |

| PILOT PRESSURE | 0.25~0.5MPa |

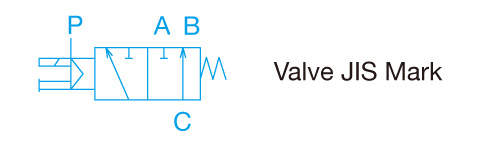

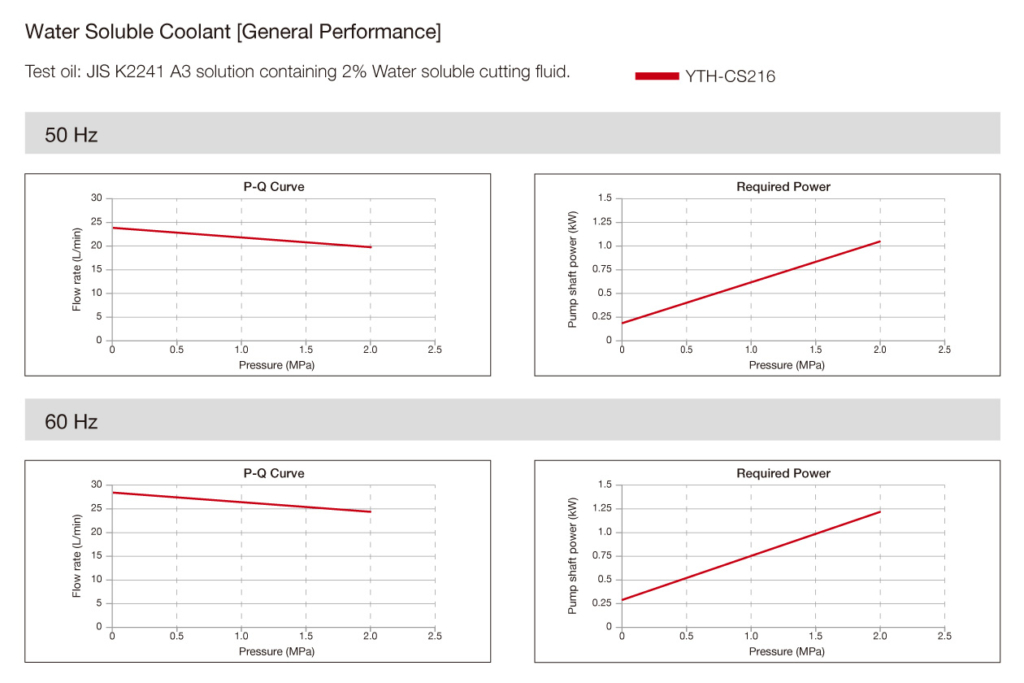

PERFORMANCE CURVES

YTH-CT/CS

YTH-CT

YTH-CS

YTH-CS LINE TYPE

*The model number of Line type ends with capital letter “L.” The pump specification is the same as YTH-CS.

NOP Filter Pump External Type

Unlike normal type that can only be installed upon a coolant tank, this external type can be installed independently in a distant place with an extension pipe.

Alteration of tank cover is no longer necessary, allowing quick and easy retrofitting.

For the actual appearance, please refer to the DIMENSIONS.