E SERIES

A TurbulenceTM filter is built in

This is a YTH High-Spec Series.

E SERIES

A TurbulenceTM filter is built in

This is a YTH High-Spec Series.

An All-in-one, Medium Pressure Coolant Pump

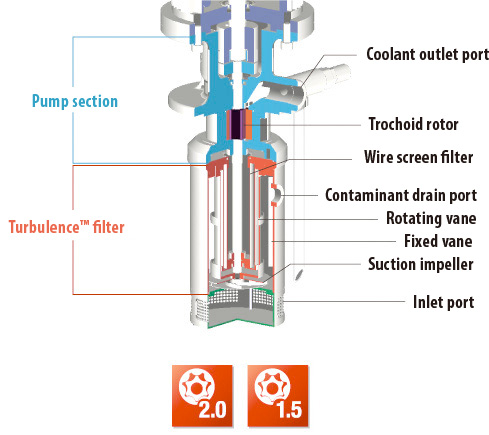

All components of a coolant system are consolidated into a single YTH unit. No line and suction filters are required. The use of YTH-ET reduces the required space to about 1/20th by volume of that occupied by a conventional coolant system.

The saved space expands the available plant space, resulting in a higher production efficiency.

| Turbulence™ filter With turbulence action, the sludge sticking to the filter is cleaned, rendering the filter clog-free. |

|

| Trochoid™ pump/ 2.0 MPa, 1.5 MPa A rotor turning in a trochoidal curve generates pressure to suck and discharge fluid. This is an extremely efficient self-priming pump. |

|

| Compatible with the TAZUNA™ fluid control system (software) TAZUNA reduces the electric power cost further by approximately 20%. The pressure and flow rate are automatically adjusted. |

TOP-YTH ①②-③EVD④⑤

| ① Motor capacity | 750 : 0.75kW | |

|---|---|---|

| 1500 : 1.5kW | ||

| ② Motor type *1 | Standard motor | A3 : AC 200/200/220/230 V 50/60/60/60 Hz 3 phase electric induction motor (IE3) with CE marking |

| Local motor | AE: supplied by NOP Deutschland (Germany) AF: supplied by NOP Taiwan AJ: supplied by NOP Asia (China) AK: supplied by NOP India | |

| ③ Rotor capacity | T208 : Trochoid™ pump , 8 cc/rev | |

| T216 : Trochoid™ pump , 16 cc/rev | ||

| S208 : Trochoid™ pump , 8 cc/rev *2 | ||

| S216 : Trochoid™ pump , 16 cc/rev *2 | ||

| Filtering method | E : Turbulence™filter type | |

|---|---|---|

| Relief valve | VD : External return type | |

| ④ Relief pressure setting *3 | 20 : 2.0 MPa | |

| 15 : 1.5 MPa | ||

| ⑤ Filtering performance | B : 50 µm (for spindle oil coolant) | |

| C : 20 µm | ||

*1 For further details about the local motor,please contact to our overseas branch or subsidiaries.

*2 S is wear resistant type for hard and abrasive materials.

*3 Refer to specifications for the compatible model for each relief value setting.

| Model | L | B | C | W | Q | H | M | φD | ϒ(°) | TB |

|---|---|---|---|---|---|---|---|---|---|---|

| YTH750A3-T208EVD** | 638.8 | 274.8 | 93.5 | 214.8 | 20 | 364 | 253.5 | 170 | 30 | 151 |

| YTH1500A3-T216EVD** | 678.3 | 294.8 | 113.5 | 234.8 | 40 | 383.5 | 273 | 202 | 45 | 168 |

| YTH750A3-S208EVD** | 638.8 | 274.8 | 93.5 | 214.8 | 20 | 364 | 253.5 | 170 | 30 | 151 |

| YTH1500A3-S216EVD** | 678.3 | 294.8 | 113.5 | 234.8 | 40 | 383.5 | 273 | 202 | 45 | 168 |

| Model | Motor capacity(kW) | Flow rate (ℓ/min) 50Hz/60Hz | Maximum pressure (Mpa) | Approximate weight (kg) |

|---|---|---|---|---|

| YTH750A3-T208EVD** | 0.75 | 12.0 / 14.4 | 1.5 / 1.5 | 34 |

| YTH1500A3-T216EVD** | 1.5 | 24.0 / 28.2 | 2.0 / 2.0 | 39 |

| YTH1500A3-S216EVD** | 0.75 | 12.0 / 14.4 | 1.5 / 1.5 | 34 |

| YTH1500A3-S216EVD** | 1.5 | 24.0 / 28.2 | 2.0 / 2.0 | 39 |

* ④ Relief pressure setting ⑤ Filtering performance

Our special Turbulence™ design generates turbulence around the surface of filter with 2 wing-shaped

vanes rotating around filter and can wash away sludge from filter surface continuously.

| Material | Iron | Casting | Aluminum |

|---|---|---|---|

| Compatibility | Excellent | Excellent | Excellent |

| Suction strainer | 3mm (Solids larger than this must be removed in the tank) |

|---|---|

| Filter | 20 µm 50 µm(for spindle oil coolant) |

For its special wear resistant structure, S type can be installed on coolant tanks of machines which are machining materials which generate hard and abrasive Chips.

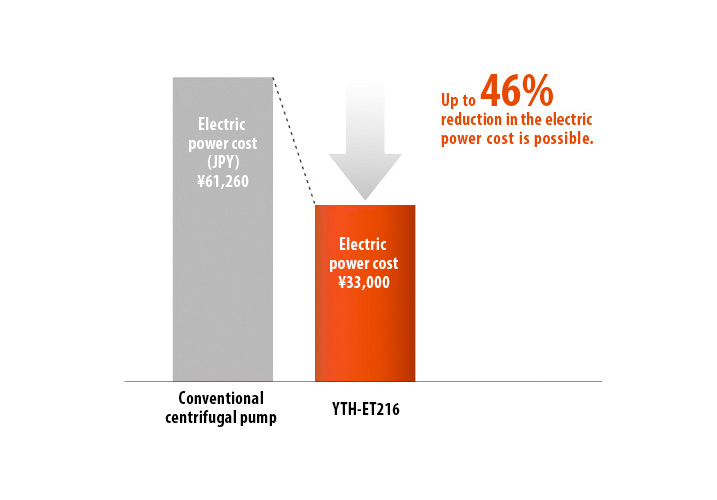

The use of YTH-ET results in huge energy savings over the conventional centrifugal pumps. The electric power cost is greatly reduced.

Oil used: Type A3 solution containing 2% water-soluble cutting

※ The maximum pressure of ET208,ES208 is 1.5 MPa.